Contact Now

Your benefits with our extrusion dies

We develop our aluminium extrusion dies in close cooperation with you. We have a common goal, to have an optimal extrusion process. For this reason we developed the unique Technologies resulting in the following benefits:

- Enhancing press capabilities

- Significantly increasing the die stability

- Longer die life, less costs

- Reducing the number of trial runs, hence loss of time, thus cost reduction.

- We trust in improving dies quality.

Our Facility

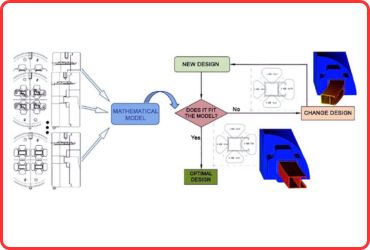

Design

Band saw Machine

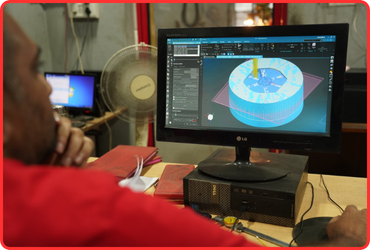

Computer Programming

VMC Machine

Hardner Tester

Hydraulic Surface Grinding Machine

Manual milling Machine

Wire cut Machine

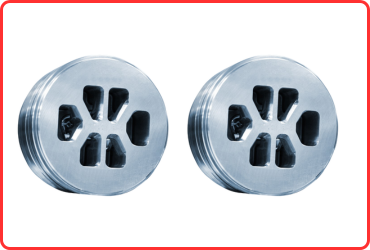

Die Finishing

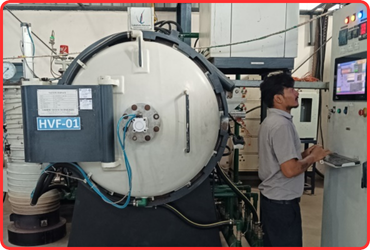

Vacuum heat treatment

EDM Machine

WHY CHOOSE US

We are creative& professional

We Are Creative

The Art of die manufacturing resonates within the walls of the workshop, where skilled artisans and cutting-edge technologies converge to craft precision dies for structuring aluminum products.

Honest And Dependable

We specialize in high-quality aluminum extrusion die manufacturing, delivering precision-engineered solutions for diverse industries. Trusted for our reliability and commitment to excellence, we ensure customer satisfaction in every project.

Quality Commitment

We are committed to delivering precision-engineered aluminum extrusion dies and solutions with uncompromising quality and reliability, meeting the highest industry standards. Our dedication ensures superior performance, durability, and customer satisfaction in every product.